The Team of Underwater Operation Technology and Equipment

1. Introduction

The Team of Underwater Operation Technology and Equipment is in the College of Mechanical and Electrical Engineering, Harbin Engineering University. It is an academic research organization that integrates teaching, research, production, and practical application. Since the 1970s, aiming at the practical requirements of ocean energy engineering and the defense military, the team has intensively studied the technologies about deep-sea explorations and productions, underwater operations, Navy rescues, special operations, bionic operations, etc. In 2004, Professor Xu yuru, an academician of the CAE Member, led the establishment of the Heilongjiang Provincial Key Laboratory of Underwater Operation Technology and Equipment. In the past 20 years, our team under the lead of Professor Wang Liquan mainly studied and developed the equipment of underwater operation systems, connection technology of underwater production facilities, sealing technology for deepwater scenarios, deep sea operation and equipment, marine bionic robots, Navy rescue operation and equipment, underwater docking technology, offshore wind power equipment, special equipment, etc. Moreover, our team maintains close cooperation with famous enterprises and universities worldwide, including the research institute of China National Offshore Oil Corporation, Offshore Oil Engineering Co. Ltd, Kunming Ship Equipment Research and Testing Center of CSSC, China Ship Scientific Research Center, China Nuclear Power Technology Research Institute Co., Ltd, China Classification Society (CCS), Det Norske Veritas (DNV), etc.

Until now, our team has undertaken 5 subprojects of major national R&D projects, 5 subprojects of the national high technology research and development program of China (863), 10 NSFC projects, 13 projects of the high-tech ship and 2 innovative projects supported by Ministry of Industry and Information Technology of the People’s Republic of China, 4 projects of National Key Research and Development Program of China, 3 opening fundings of National Key Laboratories, 8 projects of Natural Science Foundation of Heilongjiang Province of China, and other 76 enterprise cooperation projects.

Until now, our team has won 3 first-class prizes, 3 second-class prizes, and 4 third-class prizes from Heilongjiang Scientific & Technological Achievements, 1 first-class prize, 2 second-class prizes, and 2 third-class prizes from the Prize for Progress in National Defense Science and Technology of China, 2 second-class prizes from the Prize for Progress in National Energy Science and Technology of China, 2 second-class prized from the Prize of Ocean Engineering Science and Technology, and one Patent Prize for Ship and Ocean Engineering. The graduate students in our team also won many awards from the competitions about science and technology innovation, including 1 outstanding winner, 6 First Prize, 6 Second Prize, and 3 Third Prized.

Currently, there are 11 full-time teachers in our team with 4 professors and 7 associate professors. There are also 4 associate researchers and more than 100 graduate students.

2. Research interests

2.1 Marine Engineering Equipment

(1) Subsea Control System

The Subsea control module is a core equipment of the underwater control system, which is one kind of supporting equipment for marine oil and gas resource extraction. The module has the ability to control valves of subsea Christmas tree, monitor and feedback on the condition of production equipment undersea, and coordinate the production systems above and under water. The electro-hydraulic composite and all-electric control module have been developed and applied in engineering.

(2) The Connection Technology of Underwater Production Facilities

Aiming at the mechanical connection demands on subsea Christmas Trees, manifolds, jumper tubes, and riser pipes, our team developed different kinds of underwater connectors including deepwater gripper-type connectors, claw-type connectors, clamp-type connectors, and bolted flange connectors. As the basic theory, the contact sealing mechanism and manner under deepwater scenarios are studied accordingly.

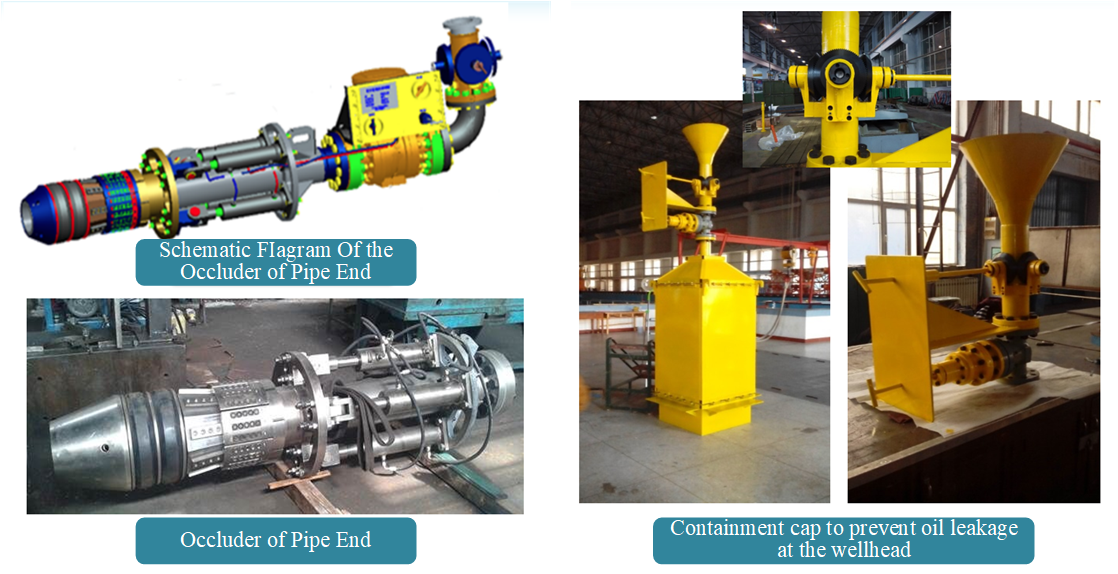

(3) The Technology of Underwater Emergency Maintenance

Aiming at the pipeline burst issue of marine oil and gas production system that would cause crude oil leakage, our team proposed a complete scheme for emergency maintenance. A series of principle prototypes and devices are designed, such as submarine pipeline plugging devices, oil control covers, underwater diamond wire saw machines, etc. The core scientific problems are intensively studied including the cutting efficiency of the diamond wire saw machine and the rubber seal of the oil and gas pipeline.

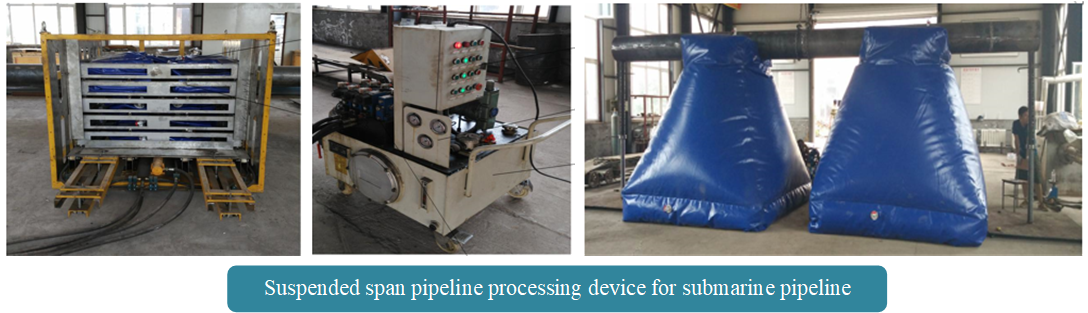

(4) The Technology of Offshore Platform Installation and Submarine Pipeline Laying

Aiming at the tendon connection problem of Tension Led Platform (TLP), our team designed a series of dedicated devices, including the connection device for the tensioned riser of TLP, tensioner, and temporary buoyancy device. For the demands on the construction of offshore platform pile foundation, our team also designed several dedicated devices, such as internal expansion pile hanger, single/bilateral pile hanger, steel pile flipper, pile gripper, jacket leveling equipment, submarine cable towing auxiliary device, etc. Regarding the laying of offshore oil and gas pipelines, relying on the Reel lay pipeline laying system, our team designed a pipeline tensioner, a drum driving device, and a steel pipe pairing machine. Moreover, several devices are designed for the submarine pipeline laying, including gutter-plough, Jet trencher, and backfill plough.

2.2 Underwater Robot

(1) Underwater Manipulator

Our team has developed manipulators with five or six degrees of freedom (DOF) for underwater operation. The manipulators can autonomously replace the operating tools with electro-hydraulic servo control. Different capture schemes and ultrasonic testing methods are studied targeting practical foreign object grasping and pipeline weld inspection scenarios.

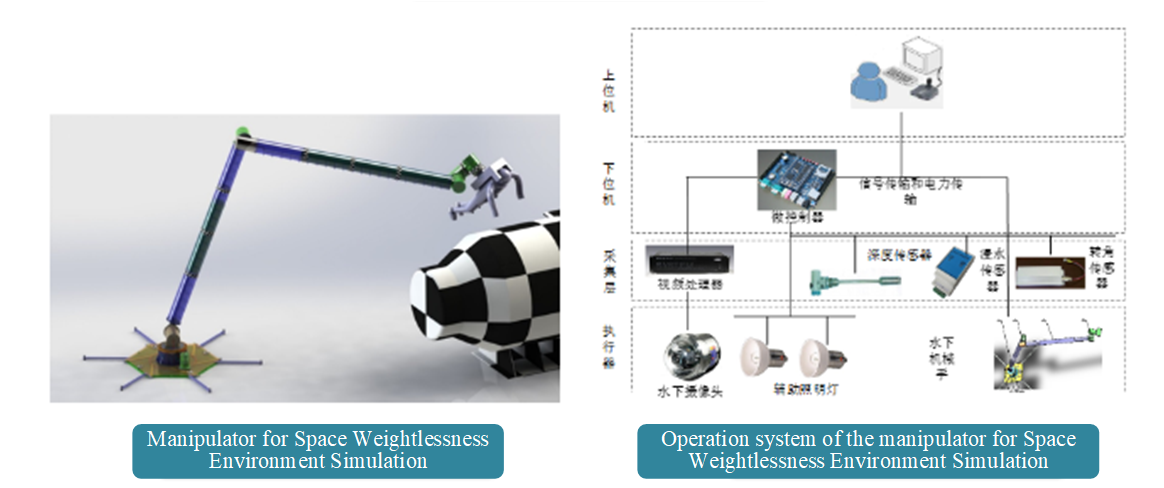

We also researched the underwater weightlessness simulation scheme for space six DOF manipulator. The simulation scheme meets the technical requirements, especially on motor load, joint sealing, control accuracy, weightless balance state, etc.

(2) Special Robot

We have developed various mobile cleaning robots for offshore platforms such as steel piles, hull surface maintenance, and trenchless pipe diameter laying. These robots can remove impurities such as shellfish and rust on the surface without affecting the platform's operation and hull berthing. Based on the principle of creep, the impact crawling method is used to carry out perforation operations in the soil, achieving underground non excavation laying of cables, optical cables, and other pipelines.

2.3 Visual Simulation Technology for Underwater Operations

Through collecting real-time monitoring data, the mathematical model of the considered ship could be identified. Then using the 3D visual simulation technology, the moving attitude of the ship is illustrated in time. This technology could be applied for engineering rehearsals and operator training of offshore operations, such as pipe laying and lifting operations.

3. Achievements

3.1 Subsea Control System

In response to the core technology and equipment manufacturing issues of subsea control systems, the first 2000-meter level electro-hydraulic composite subsea control system for underwater production facilities in China has been developed. The actual underwater test and high-pressure chamber test have been completed in Shenzhen. We also developed the first 500-meter level all-electric subsea control module, filling the technical gap in the field in China. In this research field, we have completed 4 projects of the high-tech ship from the Ministry of Industry and Information Technology of the People’s Republic of China, 2 projects of the National Key Research and Development Program of China, and 3 enterprise cooperation projects. 12 academic papers are published and 13 invention patents are authorized.

3.2 The Connection Technology of Underwater Production Facilities

Contact static sealing is a core mechanism for deep water connection technology. Our team has conducted a series of research work in this area, establishing a complete set of theoretical research methods and numerical simulation techniques. In this research field, 50 academic papers are published and 40 invention patents are authorized. Based on the research on contact static sealing, we have developed the world’s first gripper-type mechanical connector for submarine pipeline connection and offshore platform pipeline connection which has passed the certification of the China Classification Society (CCS).

We also have invented and developed a series of CCS-certificated 3000-meter level connection equipment for the production system of deep-sea oil and gas fields, including deepwater gripper-type connectors, deepwater clamp-type connectors, and deepwater bolted flange connectors. The corresponding project “Research on Deepwater Pipeline Connection Technology and Equipment Development” won the first-class prize from Heilongjiang Scientific & Technological Achievements (Invention) in 2016. The developed deepwater clamp-type connector is the first practical-applied one in China certified by Det Norske Veritas (DNV). In 2022, the connector has been applied in Ledong 22-1 oil and gas field in the South China Sea.

In this research field, our team has completed 2 subprojects of the national high technology research and development program of China (863), 3 projects of the high-tech ship from the Ministry of Industry and Information Technology of the People’s Republic of China, 3 NSFC projects, 1 project of Natural Science Foundation of Heilongjiang Province of China, and 4 enterprise cooperation projects. 56 academic papers are published and 41 invention patents are authorized.

3.3 The Technology of Underwater Emergency Maintenance

In this field, we developed a series of underwater emergency maintenance tools including the first diamond wire saw machine in China, underwater multifunctional work tools, pile hangers, pile grippers, leveling devices, and work tools for divers. This research fills the gap in the installation, detection, and maintenance technology of large underwater pipelines in China, achieving a significant breakthrough in the cutting technology of deep-sea engineering pipeline. 1 NSFC project and 1 opening funding of National Key Laboratories have been completed in this research field. According to incomplete statistics, more than 30 academic papers are published and 20 invention patents are authorized.

3.4 The Technology of Submarine Pipeline Laying

We developed the first engineering prototype gutter-plough for submarine pipeline laying, and the first test prototype machine for deep sea flexible pipeline laying. 2 subprojects of major national R&D projects, 1 project of Heilongjiang Province Science and Technology Research, and 5 enterprise cooperation projects have been completed. 11 academic papers are published and 4 invention patents are authorized.

3.5 Underwater Robot

(1) Cleaning Robot for Ships

The robot has the ability to clean shellfish, rust skin, and rust spots attached to the surface of ship hulls. The purpose is to reduce the fuel consumption and extend the service life of ships. We conducted a series of research on the mechanism of ship surface rust and organism removal.

(2) Biomimetic Mechanical Crab

Aiming at the amphibious environment detection scenarios, we developed a biomimetic mechanical crab that has the advantages of good terrain adaptability, smooth movement, low energy consumption, and high efficiency. Several critical issues such as sealing technology for amphibious multi-legged biomimetic robots, adaptive methods for complex terrain, gait switching methods, multi-legs coordination technology, and compliance control methods have been researched.

(3) Research on Coupled Propulsion of Underwater Dual Swimming Paddles for Amphibious Biomimetic Multi-legged Robots

Through biological observation and analysis, the dynamic modeling, hydrodynamic analysis, propulsion mechanism design, simulated environmental testing, and shallow beach environmental testing for the Amphibious Biomimetic Multi-legged Robots have been widely researched.

(4) Manipulator for Space Weightlessness Environment Simulation

According to the special requirements of astronaut training, we designed and developed a 10m long six degree of freedom manipulator to simulate the weightlessness environment in space. In order to ensure the reliability, the mechanical design, motor load, sealing methods have been researched.

(5) Other Special Robot

Detection robot of nuclear steam generator; Medical Robotics; Underwater welding manipulator; Marine zero buoyancy comprehensive non-destructive testing carrier platform.

In this field, we got 2 NSFC projects, 1 research project of aerospace, 2 projects from the Natural Science Foundation of Heilongjiang Province of China, 1 project of Heilongjiang Province Science and Technology Research, and 5 enterprise cooperation projects. 62 academic papers are published and 16 invention patents are authorized.

3.6 Visual Simulation Technology for Underwater Operations

For the deepwater crane and pipe laying vessel "Offshore Oil 201", we developed a visual simulation system that collects real-time monitoring data, achieves the real-time calculation of system mathematical model, and constructs and displays the actual motion posture of ships through 3D visual technology. This simulation model can be used for engineering rehearsals and operator training for pipeline laying and lifting operations.

4. Team culture

The duty-bound mission of our team is to impart knowledge and educate students. Closely around this mission, improving teaching and scientific research ability are our main targets. By establishing a more reasonable and sound talent cultivation mechanism creating a favorable environment for teacher growth, recruiting more talents, and enhancing the opening viewpoints and research development of the team. By sharing resources, providing the team members with more opportunities in high-level research projects, and accelerating the rapid growth of young talents. Ultimately, establishing a team with a sense of identity, achievement, and responsibility.